Vigas - Flexão Simples - Viga Continua 5

FLEXÃO SIMPLES

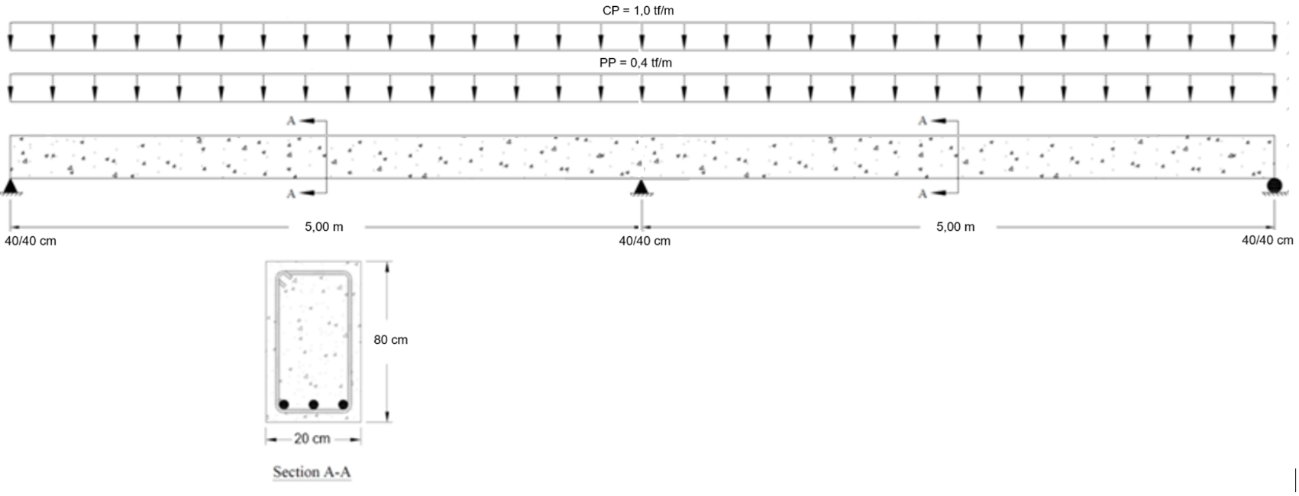

Neste exemplo, será dimensionada a armadura longitudinal e transversal de uma viga submetida a Flexão Simples utilizando como base a Norma ACI318-19, conforme dados abaixo:

Concreto - C25 (4000 psi) / Aço – ADN420 (60 ksi)

bw: 8 in / h: 31,5 in

| TQS | Software B | Software C |

| Mu+ 256,65 kip.in | Mu+ 238,95 kip.in | Mu+ 269,93 kip.in |

| Mu- 486,75 kip.in | Mu- 485,87 kip.in | Mu- 480,56 kip.in |

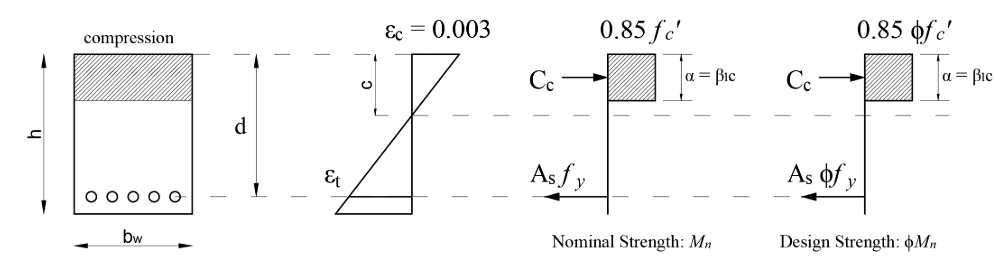

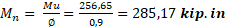

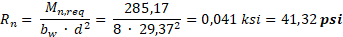

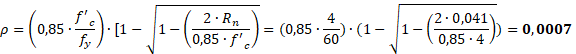

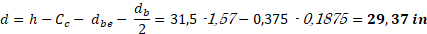

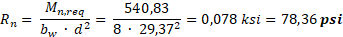

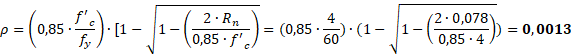

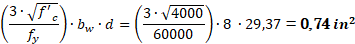

Flexão+:

![]()

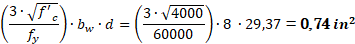

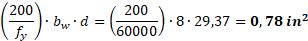

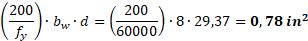

As,min (ACI 318-19 – 9.6.1.2)

![]()

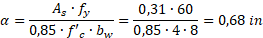

![]()

![]()

| TQS = 0,55 in² | Software B = 0,20 in² | Software C = 0,80 in² |

0,55 in2 ≥ 0,55 in2 → OK!

![]()

øMn (854,35 kip.in) ≥ Mu (256,65 kip.in) → OK!!

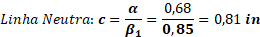

Verificação do fator de redução (ACI318-19 – 21.2.2)

0,21 ≥ 0,005 → OK! Tension Controlled! → ø 0,90 OK!

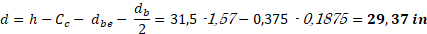

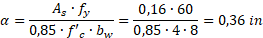

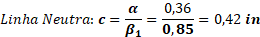

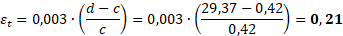

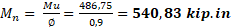

Flexão-:

![]()

As,min (ACI 318-19 – 9.6.1.2)

![]()

![]()

![]()

| TQS = 0,55 in² | Software B = 0,41 in² | Software C = 0,80 in² |

0,55 in2 ≥ 0,55 in2 → OK!

![]()

øMn (854,35 kip.in) ≥ Mu (486,75 kip.in) → OK!!

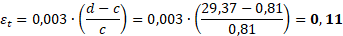

Verificação do fator de redução (ACI318-19 – 21.2.2)

0,11 ≥ 0,005 → OK! Tension Controlled! → ø 0,90 OK!

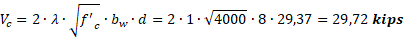

Cortante:

| TQS | Software B | Software C |

| Vu = 12,54 kips | Vu = 11,85 kips | Vu = 12,56 kips |

| Vu,design = 10,25 kips | Vu,design = 8,68 kips | Vu,design = 8,38 kips |

![]()

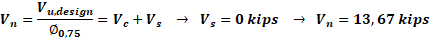

![]()

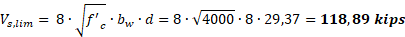

![]()

Vs ≤ Vs,lim OK!

Ø0,75 → øVn ≥ Vu → 10,25 ≥ 10,25 → OK!!

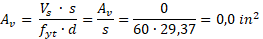

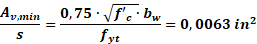

Área de Aço:

![]()

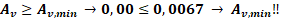

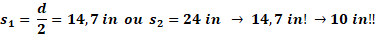

Espaçamento:

![]()

![]()

øVn (51,37 kips) ≥ Vu (10,25 kips)